Naturally, everyone wants to use the best material available when building something that will last for decades. That’s why more people are choosing galvanized steel for construction. Steel is the best galvanized metal for construction, and there are many reasons why.

Galvanized steel has all of the advantages that steel construction already has, plus the added benefit of protection from the galvanization process. Today, we’ll breakdown some of the main reasons to use galvanized steel in bridge construction.

What is Galvanized Metal?

What exactly is a galvanized metal? Galvanization is a process that protects metal by submerging it in molten zinc, thus adding a protective layer. The first benefit of galvanized metal is its known attribute of preventing future corrosion and thus ensuring less future maintenance.

As such, in the long run, businesses and governments are saving money by keeping their steel galvanized and protected. In addition, the galvanization process is environmentally-friendly and resistant to weather conditions. It’s beneficial for long-term durability and versatility.

Repairing worn-out bridges is time-consuming, expensive, and a hassle. However, galvanizing metal before installing the bridge helps to avoid this issue, especially if the metal is steel.

The Best Galvanized Metal for Construction is Steel

Any metal can be used for galvanization, though iron and steel are the most common. However, for construction, the best material is steel. Galvanized steel construction comes with all the natural benefits of steel, plus the added advantages of a galvanized material.

Steel is an effective material used frequently in construction due to its affordability, durability, and sustainability.

Affordability: Steel provides builders some expense cuts for their project budget. Its lightweight nature means less use of heavyweight equipment and lifts. Additionally, builders save money on maintenance and repair due to steel’s long life span and durability.

Durability: Although steel isn’t as heavy as other materials, such as concrete, it by no means diminishes its strength. Lightweight steel proves time and time again that it can handle a multitude of weight. That’s why it is often used in construction for railroads, bridges, and other infrastructure.

Sustainability: Steel is one of the most recyclable materials in the world. Very often the materials used for steel construction will come from recycled steel. However, this does not make it any less durable. Recycled steel’s strength and resilience is equivalent to new steel products.

Rely on the Experts in Bridge Construction

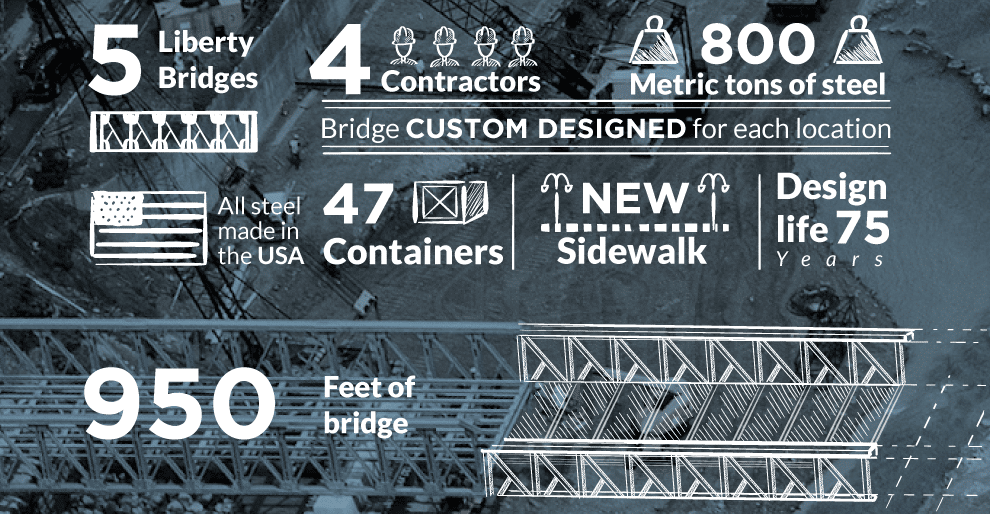

In our decades of experience, we’ve built bridges in over 50 countries around the world. We design bridges with the highest quality steel, custom-built to fit your needs.

Not only are we leaders in bridge design, engineering, and manufacturing, but we also are on-site at every bridge construction to oversee the process. No middlemen, just long-lasting steel bridges.

U.S. Bridge’s team of dedicated experts ensures bridges are made to fit your custom needs and is engineered to last for decades. Contact us today or try out our exclusive bridge scope tool for a quick proposal!