The following interview was with the CEO of U.S. Bridge, Mr. Dan Rogovin. The questions focus on, not only, the Puerto Rico Project, but also, the U.S. Bridge processes. CEO Dan Rogovin takes us on a journey of how U.S. Bridge became the leader in steel bridge manufacturing.

What is your background and how did you begin your role as CEO of of U.S. Bridge?

As a 3rd generation bridge builder, my career had long been established prior to my entrance into this world. My interest in building, paired with a long legacy of bridge builders in the family, led to my commitment to the bridge business at the age of 16. After a few summers stationed at various construction sites, I transferred over to the manufacturing side of the business. My time was spent gaining an understanding of materials and manufacturing means and methods. Shortly thereafter, in 1999, I joined U.S. Bridge full time and began focusing on growing the company’s footprint throughout the U.S.

What is the biggest determining factor you look at when assessing if you will take on a new project?

It is important to evaluate each opportunity carefully when determining an interest in each project. First, we consider if it fits within our capabilities. If so, then we evaluate the time frame in order to ensure that we meet the customer’s delivery requirements. Lastly, we determine whether this project would provide some meaningful benefit to the Company. If so, then the decision to participate in the project would be made.

How do you see the future of the construction industry domestically and internationally?

The infrastructure in our country is without question aging. Much of it was constructed decades ago and after years of abuse, and / or lack of maintenance, these bridge assets are subjected to the heaviest of loads under the most extreme conditions. Funding must be allocated towards the replacement of these structures. Doing so would ensure the safety of the traveling public while jointly creating thousands of jobs throughout our country.

Is U.S. Bridge positioned for international aid in catastrophes such as Hurricane Maria?

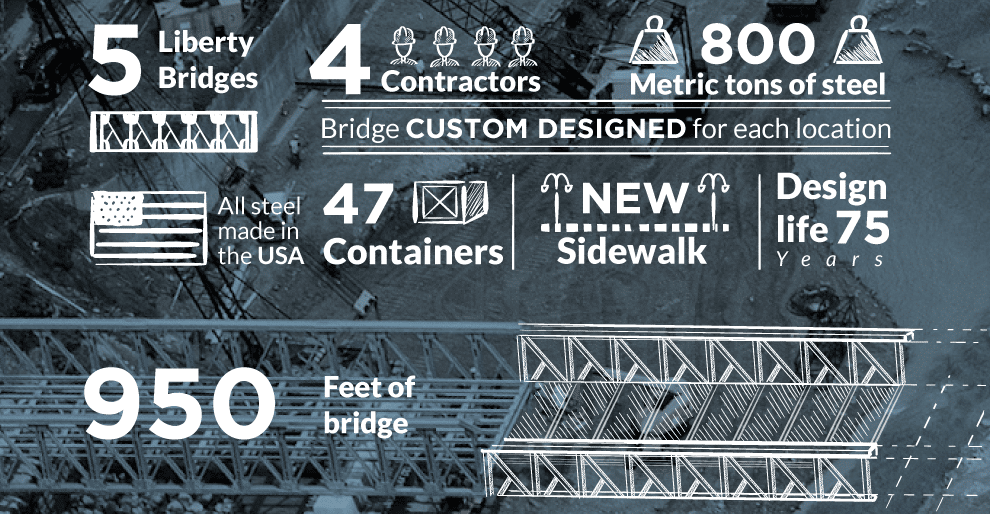

Hurricane Maria was a historic and tragic event. With thousands of lives lost and many still recovering from the massive destruction that the storm brought, it truly was a life changing event for many. U.S. Bridge is uniquely positioned to provide immediate aid and assistance for these types of events. Immediately after a storm of this magnitude, lines of communication must be restored. As such, when bridges are destroyed, it is imperative that they be replaced as quickly as possible so recovery efforts aren’t interrupted. With a complete line of bridges ready to deploy to these locations, U.S. Bridge has developed an emergency response program to help communities in need at a moment’s notice.

How did Puerto Rico find out about you and the work that you provide?

Over the past few decades, U.S. Bridge has worked diligently to establish a name for ourselves. I believe we have successfully developed a reputation for providing a quality product that meets or exceeds industry standards at a fair price, all while striving to exceed customer expectations. Shortly after Hurricane Maria made landfall and the magnitude of destruction was understood, we were contacted by contractors on the island who were in desperate need of assistance. It was clear to them that U.S. Bridge had the experience and expertise along with the passion and unrelenting energy to meet the accelerated demands required for their projects. Working closely with FHWA and FEMA, the U.S. Bridge team worked tirelessly through the December holiday season to enable the residents of Puerto Rico to reconnect and rebuild their lives.

What is a typical bridge build time?

Every bridge project is different. While some are larger than others, from the time U.S. Bridge receives notice to proceed, many bridges can be engineered, manufactured and delivered within 6-10 weeks.

How would countries and foreign governments benefit from being networked with you?

Over the past 80 years, we’ve engineered, manufactured, and constructed thousands of bridges. Based on that, we have obtained and retained an abundance of tribal knowledge that simply can’t be replicated. Each project is different and there is no boilerplate solution. Our adept team, the systems that we have refined, and our almost century of experience, undoubtedly allow us to hold the hand of any owner, and provide them with the individual support and assistance that each requires.

Where do you see U.S. Bridge’s success stemming from?

There is no question about it, our team. U.S. Bridge has a terrific team of intelligent, driven, passionate, and creative professionals that are always striving to reach new heights. Without them, U.S. Bridge wouldn’t be what it is today, an incredibly efficient, proficient and agile company that provides quality products that literally connect millions throughout the world.

What differentiates U.S. Bridge from other bridge companies? Both foreign and domestic?

U.S. Bridge is unique in that we possess the ability to engineer, manufacture and construct bridges. Many bridge fabricators have developed the skills to manufacture while leaving the engineering and construction to others. With the ability to provide turn-key services, the process is far more efficient for our clients.

What is the preferred method for organizations to get in touch with you about their next project?

I always prefer speaking with someone directly over other forms of communication. I find it far more more personable and efficient. That being said, U.S Bridge is available to provide support by dialing 888-852-0094. In the event that a client’s preferred method of communication is electronic, support can be provided by simply emailing info@usbridge.com or by visiting our website, usbridge.com, and beginning a chat session with one of our bridge experts.

Thanks Dan Rogovin for spending sometime with us on what makes U.S. Bridge a fantastic company!