All October long, organizations such as NCCER and BYF raise awareness about the diverse career opportunities in the construction industry. This event is called Careers in Construction Month and it takes place every year to help organizations reach more talented applicants as well as teach the public about the benefits presented in the industry.

The Benefits of Working in Construction

Versatility

Another big advantage of working in this industry is the extensive range of trades available. Just one project alone requires individuals from various trades like engineers, architects, masons, and many more. With so many different crafts and trades options to choose from you’re sure to find something you’ll like.

Job Security

There’s been a shortage of skilled workers for years so the demand for individuals in construction careers is high and only rising. Although the shortage causes issues such as delaying projects or not having enough manpower, it does give more people the opportunity to apply in the field. Not to mention, it provides a sense of job security.

No Degree Necessary (Degrees are Optional??)

One of the biggest advantages is that, for the most part, no college degree is required. This opens the door for many people who either chose not to go to college or were unable to afford it. However, this does not apply to every career option in the industry. For example, although a mason may not require a degree, the position of architects and civil engineer does.

Some trades, however, do require formal training or certification from either a trade or technical school but for many, you’re able to apply and join as a laborer to gain experience. Of course, like in any other industry, the more training, experience, and credentials an applicant has, the better off they will be at obtaining a job.

A More Active Lifestyle

Unlike other occupations, chances are you won’t be sitting all day. Working in construction means that you get a more active lifestyle which is better for your health. That being said, the construction industry can be very physically demanding and could have some serious negative effects on your body. Ultimately, your daily routine will be determined by the career chosen.

The Potential for Growth

Your pay depends on various factors such as location, trade, and experience. But the great thing is that there’s always a potential for growth in salary and position.

Compared to other careers, it’s fairly easy to enter a trade without experience. For many traders, you can start as a laborer and learn the craft over a few years to progress in your skills and position.

Careers in the Construction Industry

Architect

Architects are the individuals who design new buildings and construction plans. Their blueprints and concept designs include the inner structure and outward appearance of projects. This position requires a Bachelor’s Degree, Master’s Degree, or Project Management Certification. In addition, skills utilized in this career are creativity, computers, detail-oriented, math, and teamwork.

Average salary per year – $87,500

Carpentry

Carpenters build and repair frameworks and structures with wood and other materials like wood, plastic, fiberglass, and drywall. They are often involved throughout the building process from basic layout to the finishing touches. In addition to building and maintaining structures, carpenters may also play a supervisory role for framework inspection.

This career is actually among the top 10 construction trade with the highest demand. To work in this trade, individuals typically need to go to technical school, an apprenticeship program, or a trade school. Skills required for carpenters are creativity, detail-oriented, math, and troubleshooting.

Average salary per year – $56,877

Civil Engineer

Civil engineers design and supervise the construction of large-scale construction and infrastructure projects. Since one of their responsibilities is to supervise they often go back and forth from the office and project sites. This position is vital in a construction project and the pay reflects this as civil engineers are one of the top five highest-paying jobs in the industry.

This career requires education from either Bachelor’s Degree, Master’s Degree, or Project Management Certification. Additionally, civil engineers usually have skills such as computers, detail-oriented, leadership, math, and troubleshooting.

Average salary per year – $91,790

Electrician

Electricians install and maintain the electrical and power systems in new and existing structures. This means they often work with complex wiring, circuit breakers, and also large factories.

An electrician’s career generally requires a four-year apprenticeship program that qualifies individuals for both construction and maintenance work. Additionally, some electricians also attend a technical school with programs related to safety practices, electrical code, and product training. Nevertheless, most states require electricians to have a state-issued license.

Average salary per year – $67,269

Safety Technician

Safety technicians do what you would expect— they oversee safety procedures, training, and equipment. It is their job to not only identify potential risks but also develop safety plans. If an incident occurs, a site safety technician would assist with the investigation and company reports.

This role typically requires some education from a technical school, community college, registered apprenticeship program, or industry training program.

Average salary per year – $67,720

Mason

Every brick, block, or stone used to construct walls or structural supports is crafted by masons. The most common material masons use is cement. Masons will monitor drying cement and ensure that the temperature, weather, and other elements don’t prevent the cement from drying flat.

Generally, masons begin with on-the-job training and shadowing a more experienced worker or apprenticeship.

Average salary per year – $56,784

Project Manager

Just like a project manager in any other industry, construction project managers are site leaders who coordinate, budget, and supervise projects. They oversee a variety of different teams and craft professionals from the start of the project to completion. This means that they must be a team player who is able to work closely with various individuals and create detail-oriented documents.

This position requires some training in either a Bachelor’s Degree, Master’s Degree, or Project Management Certification.

Average salary per year –$92,523

Building your future with construction careers

The list of construction careers mentioned above is only a small fraction of the careers available in this industry. There are many more positions available to consider each with varying degrees of education requirements and responsibilities.

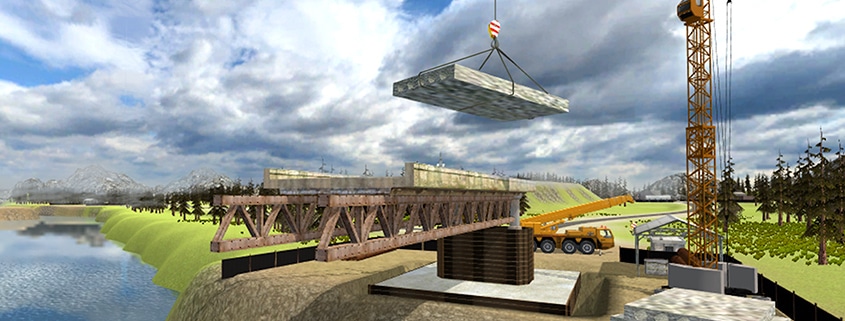

Build America together with U.S. Bridge

At U.S. Bridge, we’ve been manufacturing and engineering bridges around the world for over 80 years. Check out our bridge designs or other available services on our website!

Interested in starting your project with us? Contact us for a free quote or check our exclusive Bridge Scope tool to start building your project today.