The age of technology is in full swing, but some people fear that artificial intelligence will take over too many existing jobs and put people out of work. Others, many industry leaders included, welcome the addition of AI in the workforce. The construction industry is no exception; the use of autonomous construction equipment is on the rise across the construction sector.

What is Autonomous Construction Equipment?

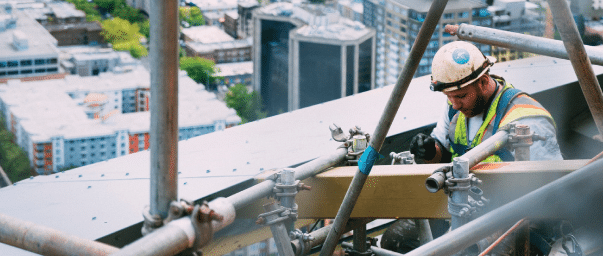

Autonomous construction equipment, such as dozers, excavators, load carriers, and haul trucks, are driverless machines that can be used to perform a variety of jobs on construction sites. These machines are typically controlled by an operator via a remote control program. This innovation has allowed many construction projects to be completed with minimal safety issues and maximum efficiency.

As the technology continues to develop and the usage benefits increase, these machines are becoming more common on job sites. Particularly, the use of autonomous vehicles (AV) has increased considerably over the past decade. In 2016, 20 states across the country introduced legislation concerning the use of AV. In 2017, that number grew to 33 states. In 2018, 15 of these states enacted a total of 18 bills regarding the use of AV.

What Does Autonomous Construction Equipment Mean for Jobs?

One of the biggest concerns around incorporating AV at construction sites is the potential negative impact on jobs. Will these vehicles take over jobs traditionally held by hard-working people and ultimately put those people out of work?

Fortunately, studies have shown that will not be the case! In fact, autonomous construction equipment could end up creating higher-paying jobs over time instead of taking them away. But this will not happen overnight, and the industry will end up changing dramatically. This transition over the next few decades is projected to raise the unemployment rate from 0.06% to 0.13%, but this indicates that jobs will be shifting in nature instead of being phased out.

For example, traditional operator roles have begun to transition to remote operators who will be operating the machinery with controllers. And these skills are in high demand!

Companies like Teleo are actively recruiting more operators and offering a position with “significantly better working conditions, making the job safer and more comfortable.” The remote control technology allows operators to safely run the machines from outside the cab, minimizing the risk of injury and providing them with a clear view of the work happening.

Times are definitely changing, and construction industry leaders are working hard to keep up. We can expect to see autonomous construction equipment on job sites across the country in a matter of decades. As such, learning the new skills of the trade will be essential to keeping up with the evolution of the industry.

Unlock Your Project’s Full Potential

We continually lead the way and incorporate the latest trends into our work. As an AISC-recognized supplier, we guarantee the highest quality steel for every project. We build durable, reliable bridges quickly, using only the best tools and techniques available to meet your unique project needs.

Contact us for a free estimate, or use our industry-leading Bridgescope tool to begin planning your project now!