Nowadays, bridges have become commonplace in our modern society. They offer great solutions to problems such as carrying heavy loads across long distances or providing a safe route for pedestrians and vehicles. But have you ever wondered how bridges are built? Here’s a quick breakthrough of the main components of a bridge and how they function.

The Main Components

The Type of Superstructure

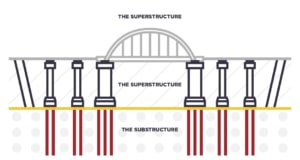

The main part of a bridge is its superstructure. The superstructure bears the weight of the load as it passes through the bridge. It comprises the deck slab, girders, truss, etc. The specific components vary based on the type of bridge and its materials such as concrete or steel.

Not only does the decking hold the load weight, but it also helps transmit the weight and pressure to the below substructures of the bridge.

The Type of Substructure

The substructure of a bridge is the component that supports the superstructure and distributes the load to the bridge footings and foundation. They consist of piers, abutments, wing walls all of which facilitate the process of transmitting the weight of the load to the earth.

Different Types of Bridges

Although there are various designs of a bridge the main components will always stay the same. The only difference is the pattern or direction in which the pressure is distributed. For example, here’s the difference between the beam and truss bridge.

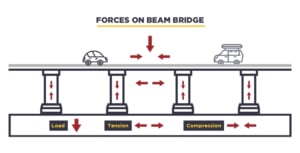

Beam Bridge

A Beam bridge, sometimes called a stringer or girder bridge, is one of the most basic types of bridge. Its design consists of horizontal beams and vertical piers that typically include two or more spans with an abutment or pier at each end. Beam bridges can be constructed using wood, steel, or concrete and are built for short distances as their only support is from piers.

In this design, the load is compressed on the top of the bridge and then applied down the piers to the earth.

Truss Bridge

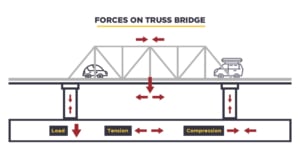

A truss bridge design involves interconnected triangles that distribute the weight over a wide space. This unique design allows the truss bridge to carry a heavier weight capacity with fewer materials. These lightweight and durable bridges can be utilized for both short and long distances.

Truss bridges function by transferring the weight of the load from a single point to a wider area. When the load is applied to the truss bridge the pressure is shared among the triangular designs for additional support and then redirected to the earth through the bridge’s substructure.

Build with U.S. Bridge

At U.S. Bridge, we work with the highest quality materials and engineers when designing and building bridges. Not to mention, our bridges are well-made, easy to maintain, and available in a variety of design and support types.

With decades of experience and our team of dedicated experts, you can feel confident in trusting an industry leader to build your bridge. Contact us today for a free quote or use our exclusive Bridgescope tool!