The federal government is heavily investing in new digital construction technologies. Recently, the Federal Highway Administration (FHWA) has awarded $16.6 million in grants to eight states through their Advanced Digital Construction Management Systems (ADCMS) grant program. The ADCMS program is part of the Biden-Harris Administration’s Bipartisan Infrastructure Law, which will award up to $108 billion in federal support for public transportation. Here is a breakdown of this grant program, the different projects being supported, and the impacts on our nation’s construction management systems.

What does the ADCMS grant program fund?

The ADCMS grant program has provided funding to support state departments of transportation to use improved data and technologies, allowing for an improved flow of digital information and building efficiencies into project delivery processes. The most recent $16.6 million of grant funding awarded in fiscal year 2024 follows an earlier round of funding that provided $34 million in grants to 10 states.

According to the FHWA website, the goals of this grant program include:

- Accelerated adoption of advanced digital construction management systems throughout the project lifecycle to boost productivity and manage complex projects.

- More timely and productive information-sharing through reduced reliance on paper.

- Development and deployment of best practices on construction sites.

- Increased technology adoption and deployment by states and local governments.

- Increased transparency as the result of the real-time sharing of information.

Acting Federal Highway Administrator Kristin White praised the states’ involved in this program and believes that these digital construction technologies will continually improve our nation’s transportation systems. She said, “These projects—which range from technologies to support the workforce, improve bid accuracy, and improve the way we communicate with the public—are leading the way to modernizing transportation.”

Digital construction technology projects funded by the ADCMS program

The funding being provided to states through this program is supporting various types of digital construction technology projects, including projects piloting new data collection, workflow standards, project development software, and information-sharing software. These projects can help combat the delays and oversights associated with ineffective paper documentation and outdated project management practices. Here are some specific examples of projects funded through this grant program:

- Maine DOT received $1,516,200 in funding for the Digital Results and Innovation are a GO for 2030 (DIRIGO 2030) project to pilot the electronic delivery of projects, improve data collection, and eliminate the need for paper documentation.

- Maryland State Highway Administration & Montgomery County DOT received $1,000,000 in funding for the Precise 3D Survey and Engineering of Transportation Infrastructure (P3DSETI) pilot project that will use cloud-based software to expedite project development and reduce the need for paper files.

- New York State DOT received $3,400,000 in funding for the Advancing Lifecycle Management of Subsurface Roadway Asset Information project that will use Building Information Modeling (BIM) to integrate data related to the subsurface of the roadway. This will save time on design and construction timelines, reducing the number of subsurface explorations.

- Oregon DOT received $1,020,000 in funding for its Item Type Library for standardized information on transportation items and features, such as guardrails, traffic barriers, signage, lighting, and numerous other transportation assets to manage these throughout their lifecycle.

This federal funding can be revolutionary in improving and modernizing our nation’s transportation infrastructure. As states move toward utilizing more digital construction technology, newly developed practices and standards will play a crucial role in improving the efficiency and safety of construction projects.

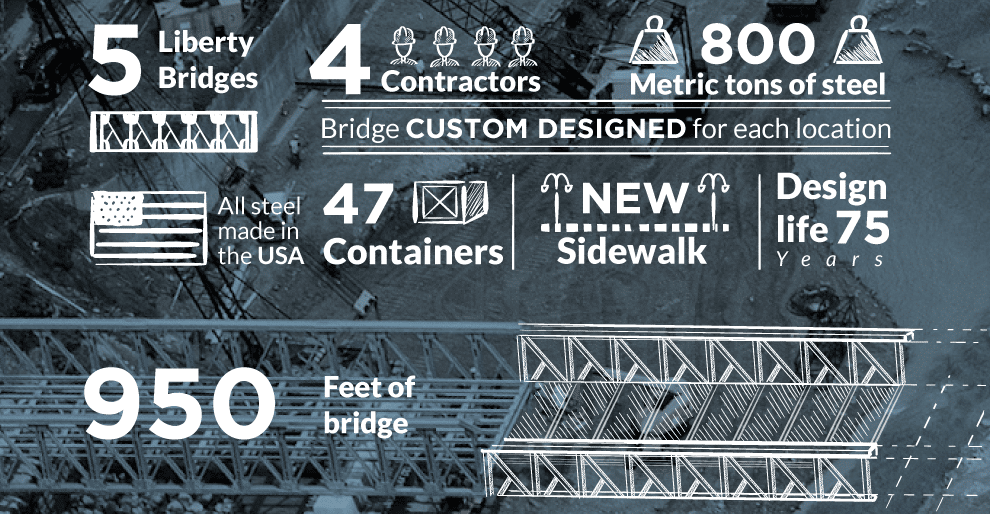

Building the Best with U.S. Bridge

At U.S. Bridge, we embrace the latest and greatest digital construction technology. If you are looking for high-quality, dedicated, and talented contractors to build with, contact our team at U.S. Bridge. We build durable, reliable bridges quickly, using only the best tools and techniques available. Our pride comes from our wide variety of prefabricated bridge designs, which will easily meet your unique project needs.

Contact us for a free estimate, or use our industry-leading Bridgescope tool to begin planning your project now!